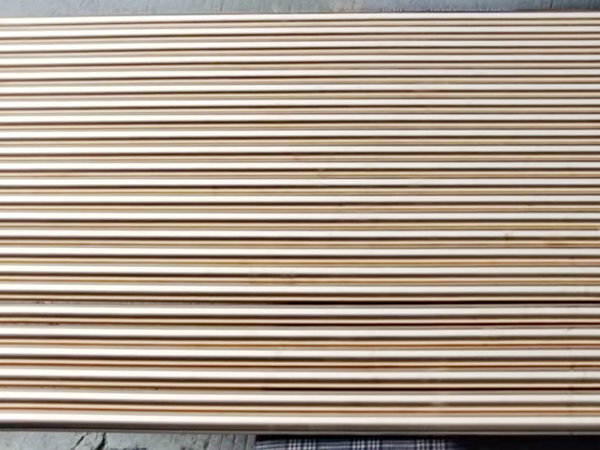

Microstructure and Properties of Beryllium Copper Alloy under Different Cooling Conditions

Date : 2025-05-29

In the production process of beryllium copper materials, annealing treatment (i.e. heating at 500-650 ℃, holding for 3-5 hours, and then furnace cooling) is commonly used to prevent work hardening during cold deformation. The results of this experiment show that heating at 500-650 ℃ and using air or water cooling methods can also achieve the goal and improve furnace utilization efficiency; Secondly, QBe2 beryllium copper alloy has a better softening effect when heated at 700 ℃ to 750 ℃ for 1 hour and then cooled by water.

Although the solution treatment temperature is relatively high (700-750 ℃), the surface is prone to oxidation, and the grains are easy to grow, experimental results show that according to conventional annealing treatment, the heating temperature is low, but the holding time is long (3-4 hours), and the amount of surface oxides is more than that produced by short-term high temperature. On the other hand, the grain size of the alloy is coarser during high temperature heating than during low temperature heating. Experiments have shown that the grain size can be controlled by process conditions to make it within the specifications. Based on the relationship between the microstructure and performance changes under different cooling conditions obtained in this experiment, the production department of this material is in charge of cold processing.

According to actual conditions, flexible cooling methods can be used to organize production reasonably. For example, in the production of beryllium copper strip, short-term high temperature (650 ° C~720 ° C) heating can be used for the work hardening effect brought by cold working, and rapid cooling can be carried out by blowing air. This can not only avoid supersaturation phase dissolution and decomposition, but also provide convenience for continuous organization production during the cold working process of the material.

Previous : 没有了!

Next : Basic properties of high-precision beryllium bronze strip