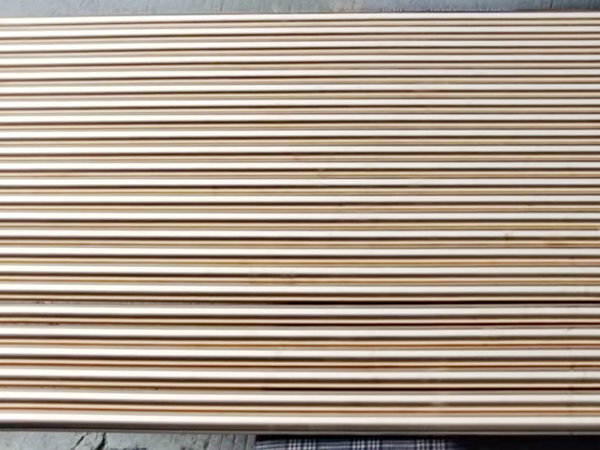

The service life of tools and molds during beryllium cobalt copper processing

Date : 2025-05-29

When beryllium cobalt copper is subjected to solid solution heating treatment in air or oxidizing atmosphere, an oxide film will form on its surface. Although it has little effect on the mechanical function after aging strengthening, the heat treatment plant will affect the service life of the tool and mold during cold processing. To prevent oxidation, it should be heated in a vacuum furnace or in an ammonia decomposition, inert gas, or restorative atmosphere (such as hydrogen, carbon monoxide, etc.).

Then obtain the heat treatment result of bright light. In addition, it is important to minimize the transfer time (during quenching) as much as possible, otherwise it will affect the mechanical function after aging. Thin materials shall not exceed 3 seconds, and ordinary parts shall not exceed 5 seconds.